Video Transcript:

Hello, I’m Bob Rice, the Head of Engineering for Control Station. Today we’re going to talk a little bit about bumped tests, which is moving the process around to observe its dynamics. And the three types of tests we’re going to talk about today are a step test, a pulse test, and a doublet test.

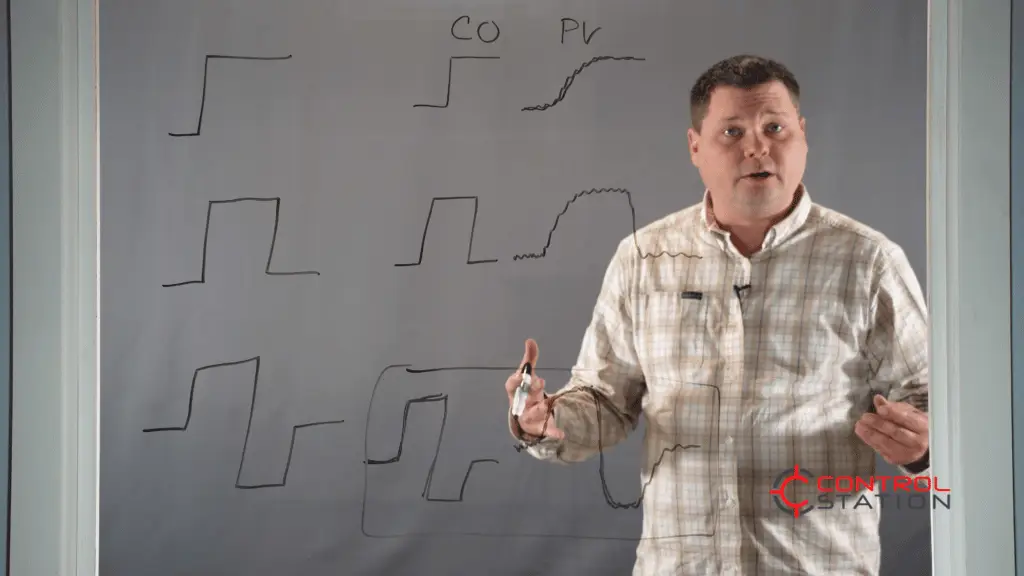

Okay, notice the shapes that I’ve drawn up here; a step test, is you’re moving the process and stepping it in one direction. In the pulse test, our two-step test is opposite in direction, you step it up, and you step it down. The doublet test builds on that. And it’s essentially two pulses opposite in direction. So we go up a little bit, down below where we started, and return.

Okay, now, what are we bumping? It depends on what we’re trying to do. We can make both open loop and closed loop types of bumps. Remember that an open loop. And the open loop is when you are directly manipulating the output yourself. So an open loop step test would be you opening the control valve, for instance, and observing what the flow does in response. So this would be your controller output or your valve; this would be your process variable. So I opened the control valve, and the flow went up. That would be an open loop step test; an open loop pulse test would be you pulsing the output up and then back down again, and your process variable will start to go up. And then it’ll come back down to where you started. That is a pulse test. Again, this is the controller output that you’ve pulled up and back down. This would be your flow that starts to go up. And then back to where it started from. The doublet test is where you’re actually moving the output up and down. So we actually start here, we open the control valve a little bit, then we close it down below where we started from, and return it back to where we originally started from. Okay, so we take our process variable, and it goes up. Because this is a control valve, we opened the control valve, and the flow went up; we closed the control valve a little bit, and it dropped back down. And then we brought it back again. So we got a little bit up, a little down, a little bit back up again.

Now, what are the benefits of each of these different types of methods? Well, we start with the step test here on the left; this is the simplest one, right? This is where we just step the output up and we observe what is happening. Now, it’s quick, it’s easy, but it only gets us data going in one direction. So if we had a heating example, where we’re adding heat to the system, that’s going to have different behavior than when we remove heat from the system, right? We may be able to heat up very quickly but cool down very slowly. All right, so we only get data going in one direction; well, we can solve that with the pulse test, right? We go up and down. So we get data going up and down. So we get heating and cooling. But if our normal operating temperature is, say, 90 degrees, we only get data going above 90 degrees, and we don’t see anything below it. Okay, so a pulse does get data up and down. But only on one side of where we are normally operating the doublet test over here on end; this is actually going to give us the most amount of dynamic information in a very short window. So here we’ve stepped the output up, we get the temperature going up, we step it down. And we actually go down below where we started from. So we get a little data above, a little data below, we get data going up, we get data going down. So we get the most amount of information in the smallest window possible.

Okay, these are open loop tests; you can use closed-loop data and a lot of analysis methods. So again, if we have a closed loop, instead of directly changing the controller output, what you’re actually doing is you’re going to step the setpoint, and the process variable is going to track that setpoint change. And what is the controller output going to do when you change that setpoint? Your controller output is going to open up to try to drive your process towards that new setpoint. So this is a closed loop setpoint change. You can do each of these in an open loop or closed loop. So again, a pulse test would be pulsing the setpoint up and down, and So we can see the process variable go up, Process Variable go down, and our controller output is probably going to go up, and then come back down again, just like it did before. The same thing with the doublet test here on end; we’re going to increase the setpoint, drop it down below where we started, and return it. process variable goes up or goes back down, comes back up again, and our controller output is moving around to do what it needs to.

Now, what is the purpose of these bump tests? Right? It’s not just to drive our operators nuts. It’s designed to help us extract some dynamic information about the process. All of these tests are designed to tell us when we move the output and what is the process variable do when we move the control valve? What does the flow do? Does it go up? Does it go down? How far does it go? How fast does it get there? All of these responses show us the same type of thing when the controller output moves; this is how the process variable responds. And that’s what a bump test is designed to do. There are a couple of factors that you have to take into account, and in the next video, we’re going to talk a little bit about historical settings in historical compression settings and Exception Settings. Alright, but here I want you to learn a little bit about open loop and closed loop bump test, step test, pulse test, and doublet test.

If you have a particular topic or an idea that you would like us to cover, please email us at askus@controlstation.com. Thank you, and I hope you enjoy this video series.