Reporting

PID Loop Tuning Technology

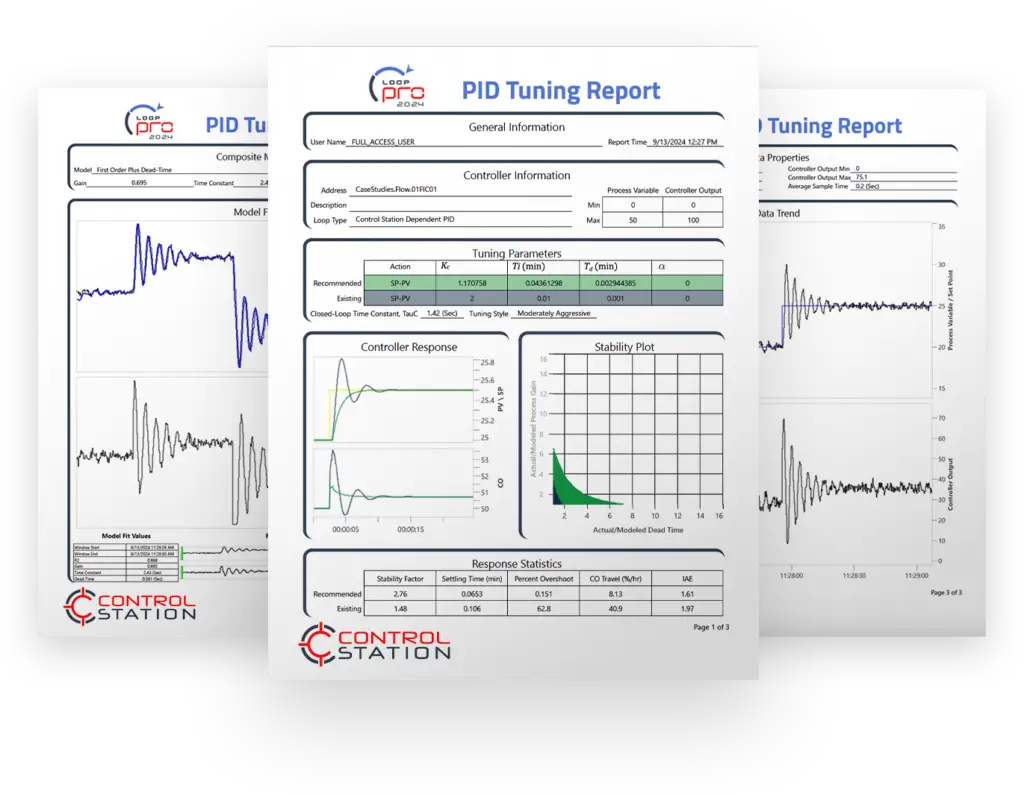

Document your PID controller tuning sessions automatically with LOOP-PRO’s Reporting feature.

Reporting

Log Each Tuning Session And Generate Reports

It’s not uncommon for production and engineering staff to forget important details while tuning PID controllers. Whether tuning is performed manually or with the help of other software tools, there are multiple steps to follow and numerous decisions to make. There is data to sample and models to calculate. Then there are decisions related to controller responsiveness and loop stability. While each choice can be helpful when reviewing results with coworkers or as a future reference resource, keeping track of those decisions and the related details isn’t easy.

LOOP-PRO understands the power of a paper trail and it does the work for you – automatically. The software logs each tuning session and it generates a report that details key analysis and decisions. From data ranges and model characteristics to response simulations and descriptive statistics, LOOP-PRO captures and records each step along the way.

SUCCESS STORIES

What customers and partners are saying about Control Station

3M

"I had a temperature differential that was low and a flow that was high. So high in fact that it required 2 chillers to run. We used LOOP-PRO to tune the process. After tuning 75 loops, the temperature differential was at an industry standard and the flow was lower. It saved us maintenance time, energy, and productivity."

Jason Rumpza

Process Control Engineer

Bigelow Liptak

"Optimizing controller performance was a breeze with LOOP-PRO. A single bump test was all that we needed to accurately model the complex dynamics of each control loop. The software’s graphics made it easy to finely tune parameters for optimal responsiveness and control. It easily reduced the time we budgeted for tuning by over 80%. It’s a truly remarkable product."

Neil Gordon

Engineering Manager

Rockwell Automation

"TUNER has proven to be an integral and valuable optimization technology for many of our process customers. Its ease-of-use and high return on investment directly align with our goals for the PlantPAx system."

Greg Hood

Business Development Manager

OSIsoft

"PlantESP is a great example of advanced diagnostic technology that enables manufacturers to capture hidden value."

Timothy Johnson

Director of Partners and Strategic Alliances

YOKOGAWA

"PlantESP includes a loop monitoring capability that delves deeply into the health and performance of PID controllers. The insight that it provides is essential to our customer’s ability to maintain profitable production."

Jorge Pinto

Manager of Advanced Solution Sales

Haverhill Chemicals

"I am consistently amazed by the flexibility and power of LOOP-PRO. With the improvements in performance we clearly understand the benefit of well-tuned control loops. This software works magic."