A level control application with numerous operating states demonstrates how to apply control loop performance monitoring software with integrated state-based analytics.

Many control loops regularly experience non-steady-state conditions. However, an application in the Canadian Athabasca oil sands production fields clearly shows why traditional control loop tuning approaches simply don’t work in some cases, and how state-based analytics can remedy the situation. Our article in the InTech February 2023 issue, titled State-Based Control Solutions for Complex Systems describes the challenges of this application, and the performance improvement realized from a state-based control solution.

Extracting oil from oil sands requires a process called steam-assisted gravity drainage (SAGD), where steam is injected into one well hole to heat and soften the bitumen, so material—containing bitumen, natural gas, solids, and water—can be pumped out of the other hole. Most companies operate large sites with multiple pads, each consisting of many well pairs. The well output must go through several separation stages, complicated by the fact that production among wells can vary dramatically.

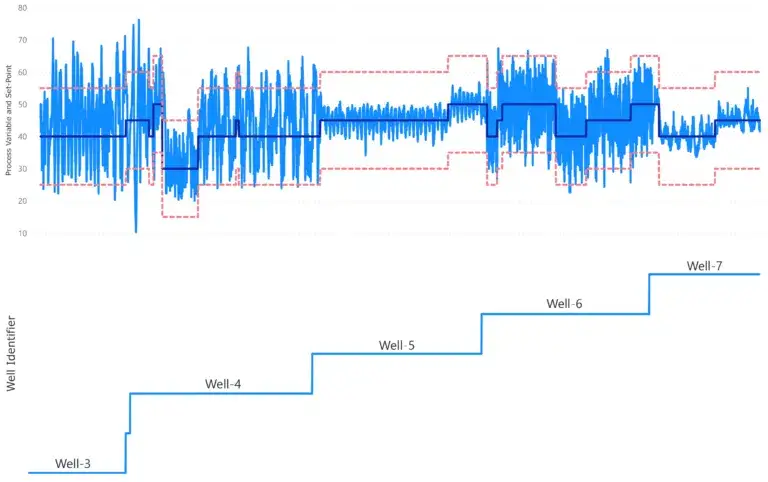

To evaluate production, a small test separator—perhaps less than 100 gallons—is often used in conjunction with piping and manifolds so that many wells can be tested individually. The test separator may be connected to each well for perhaps 12 hours, during which time the level must be controlled. However, the tuning parameters used for each test well can be very different.

Control loop performance monitoring (CLPM) tools are used to analyze operational data so users can detect PID loop control issues and optimize performance, but they are often limited to a single basic operating condition, such as when the system is running “normally.” For an SAGD application, a single level loop may operate in any one of dozens of operating states.

For applications like these, users should look to a more sophisticated CLPM tool, such as Control Station PlantESP. This software combines a wide range of monitoring and analytics tools, with the ability to assign states based on any combination of phases, products, run-time conditions, or any other production-related attributes.

For the SAGD application, there were 12 well sources—representing 12 states—which were each connected to the test separator sequentially for 12 hours at a time. Prior to using the Control Station PlantESP software, there was a distinct and undesirable performance change in level control as the test separator advanced through each well source.

Once PlantESP was used to assess the data on a per-well basis, adding the necessary context, it became clear which wells were associated with underperformance, and what tuning steps were necessary to change the situation. A key performance indicator (KPI) of average absolute error (AAE) was used to quantify performance in terms of the difference between setpoint and measured variable. Before optimization, there were many “bad actor” loops. After state-based analysis was used, the AAE was reduced significantly for each well, and operational performance stabilized.

This type of software is often needed because real-world manufacturing and production environments rarely present ideal and stable conditions. The author explains the need, and the solution.

While traditional CLPM tools have proven helpful in assessing the performance of basic loop operations, state-based analytics is showing particular value within more complex systems. The addition of state-based analytics now makes it possible for CLPM users to delve deeper, facilitating the detection, analysis, and adjustment of operational conditions that had previously stood in the way of plant-wide process optimization.

The team at Control Station would be happy to discuss how CLPM and state-based analytics can be applied to help with your applications. Contact us today.