- Standard

-

PopularPlus

| Standard |

Popular

Plus | |

- | - | |

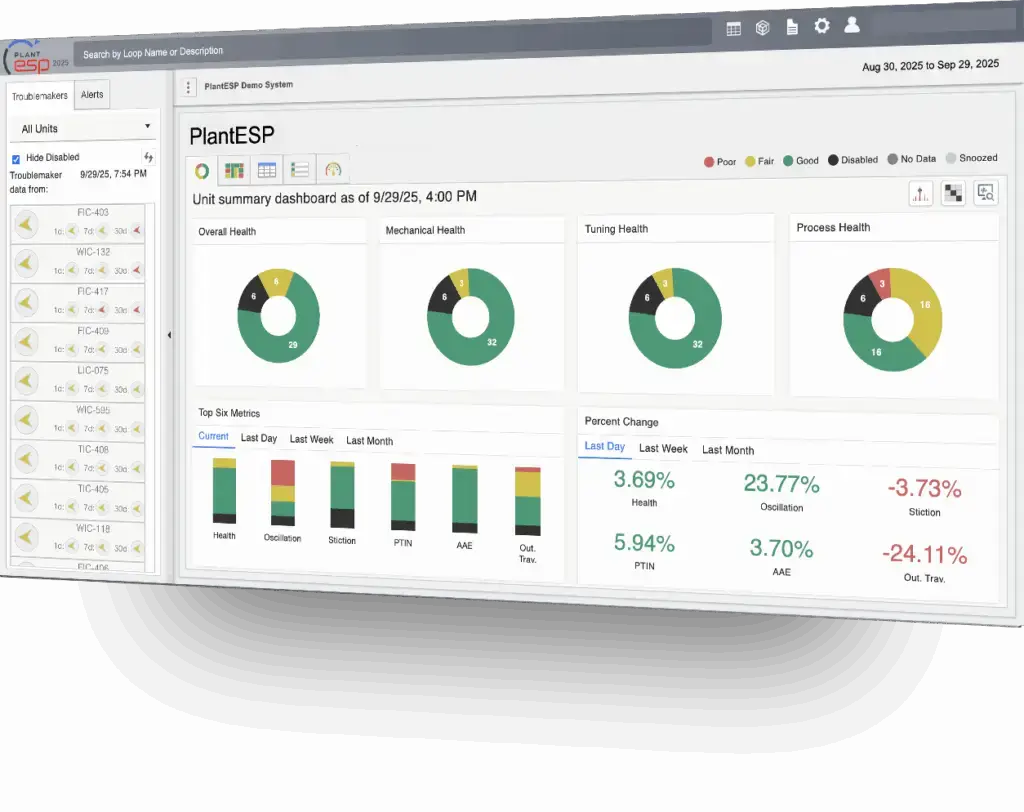

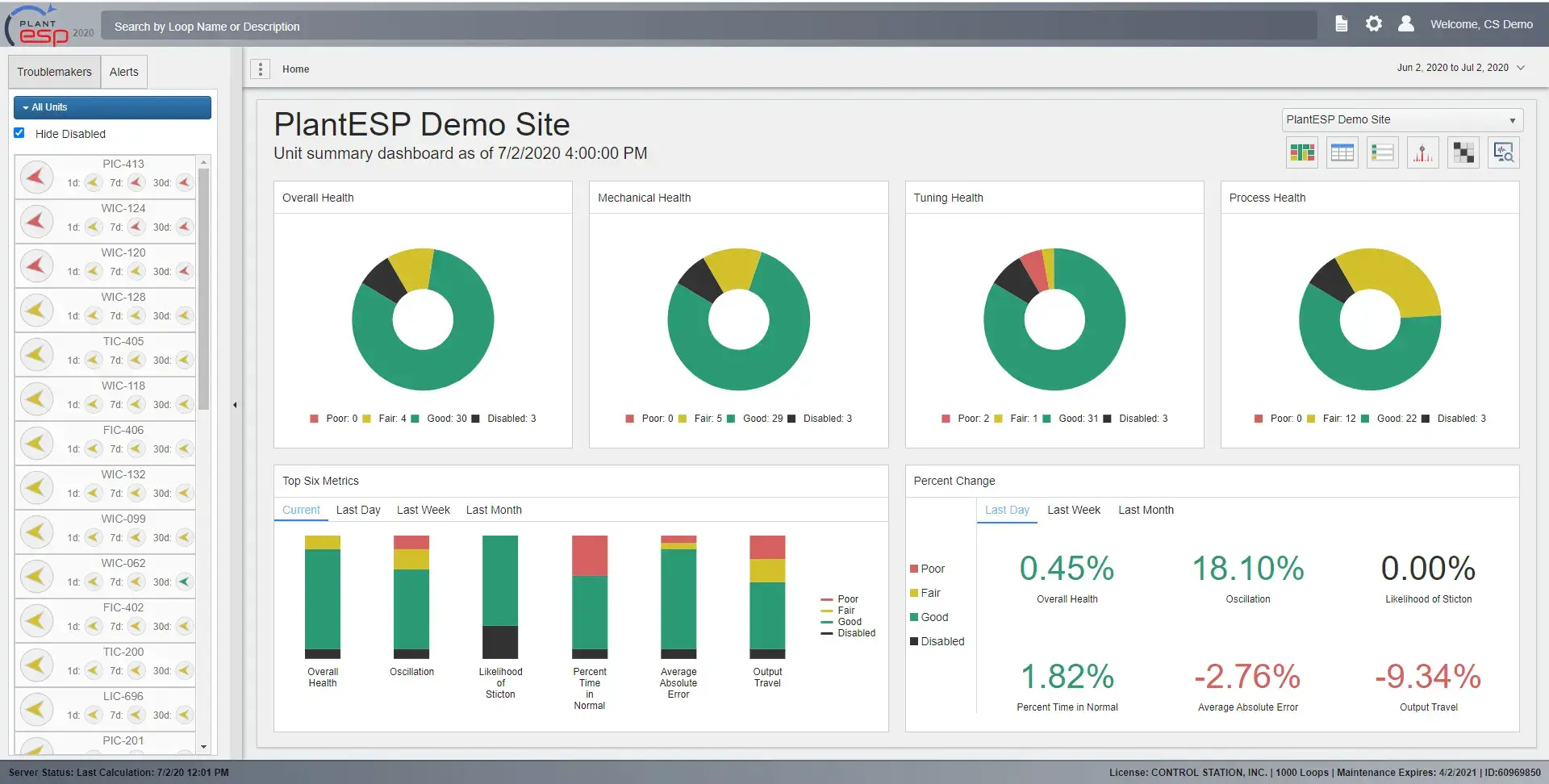

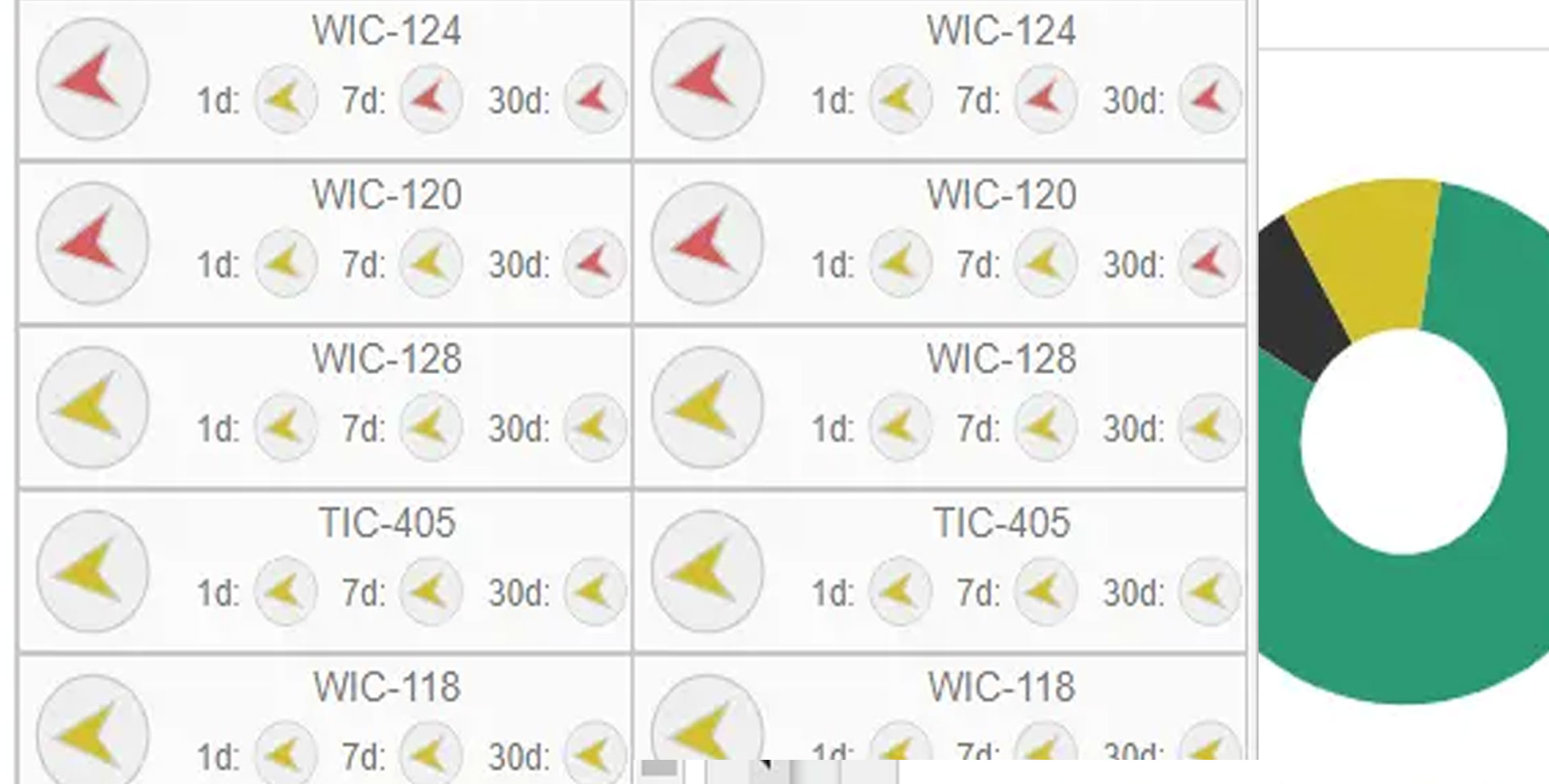

| Metrics | ||

| Standard | ✔ | ✔ |

| Valve Analysis | ✔ | ✔ |

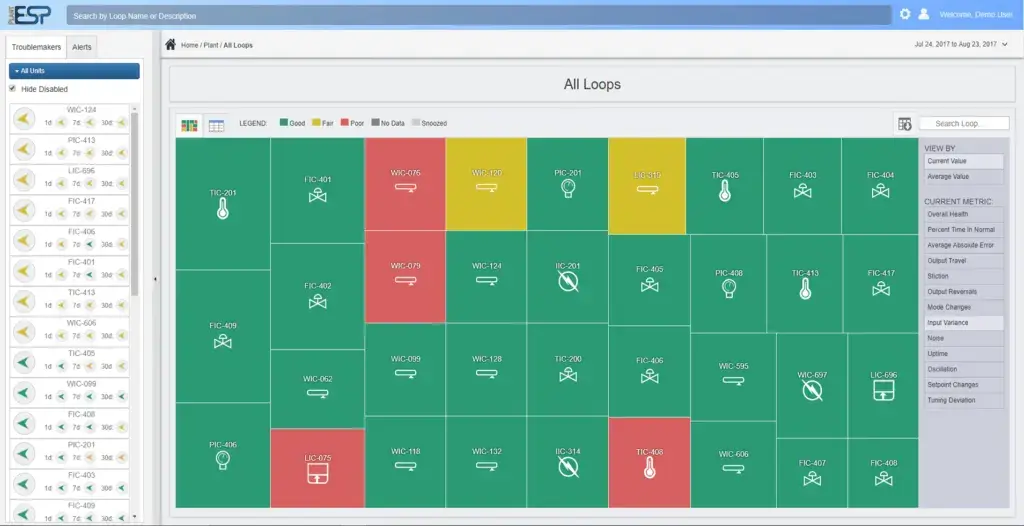

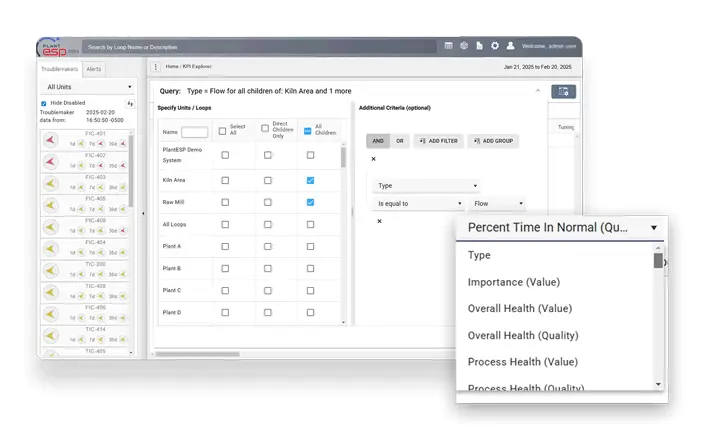

| TableVue | ✔ | ✔ |

| PriorityVue | ✔ | ✔ |

| Forensics | ||

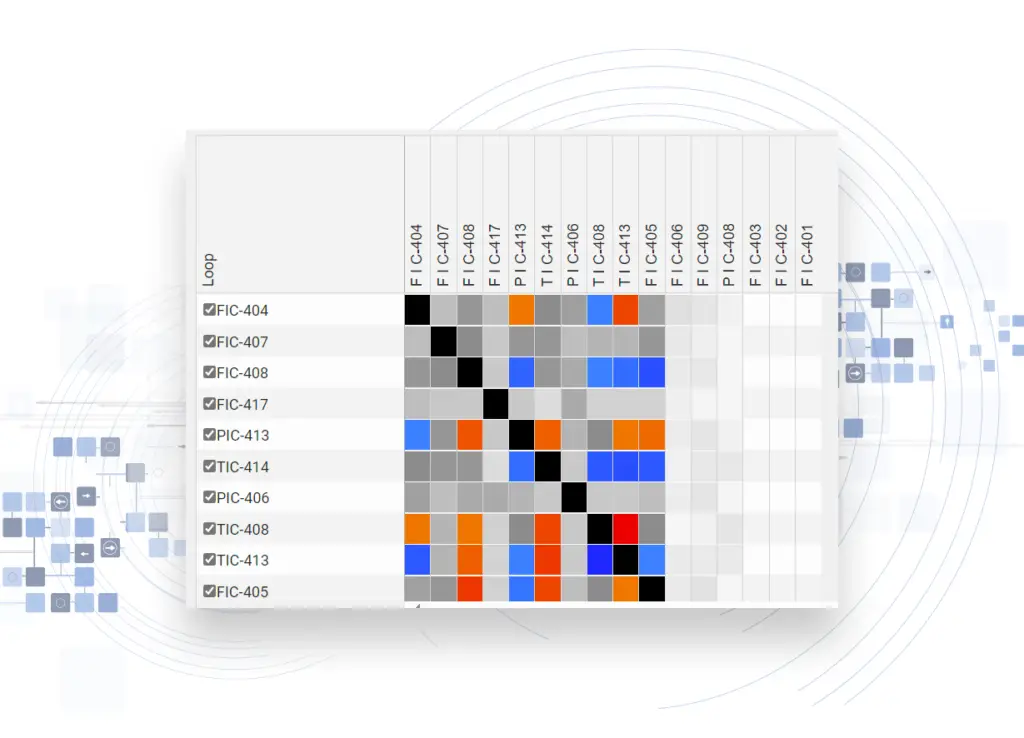

| Cross Correlation | ✔ | ✔ |

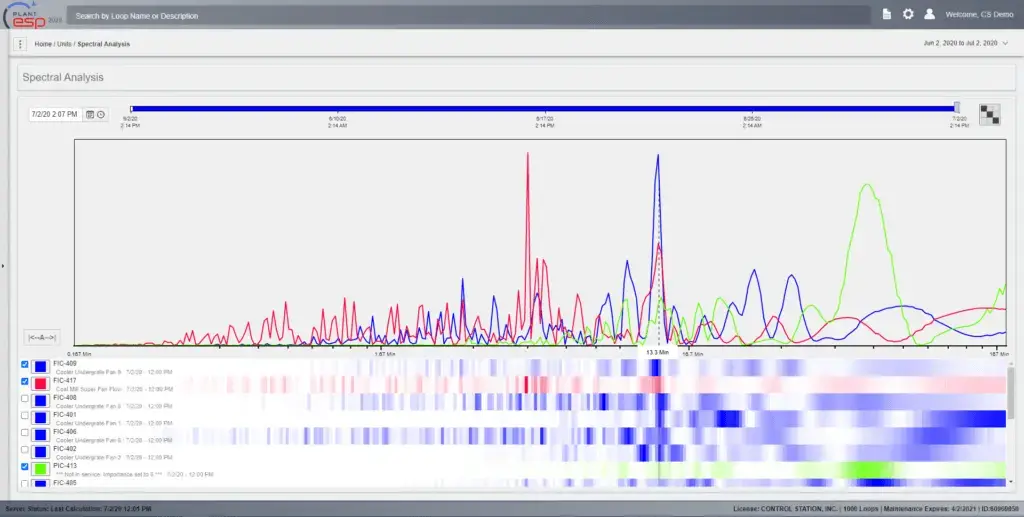

| Spectral Analysis | ✔ | ✔ |

| TuneVue | ✔ | ✔ |

| Advanced Analytics | ||

| Interaction Explorer | ✔ | |

| State-Based Analytics | ✔ | |

| Corrective Actions | ✔ | ✔ |

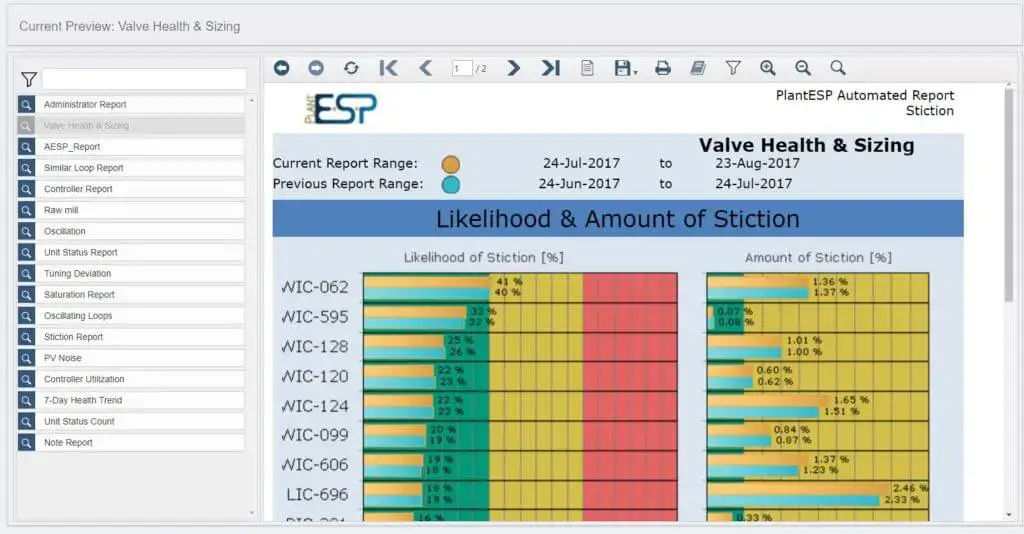

| Reporting | ||

| Web Based Reports | ✔ | ✔ |

| REST API | ✔ | Get Quote | Get Quote |